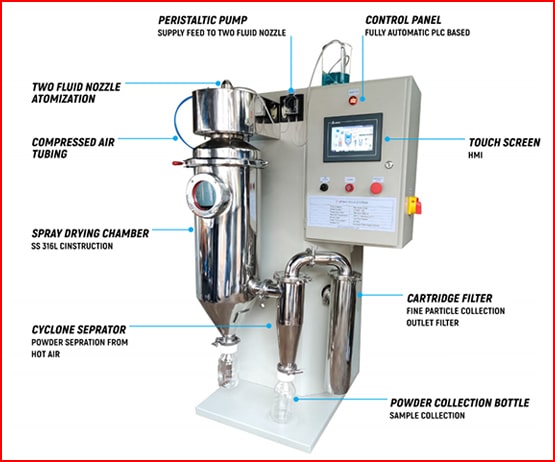

Spray Drying solutions for R & D and Production

Mumbai, Maharashtra

Monday to Saturday

Lab Spray dryer is commonly used in the conversion of liquid materials (solutions and pastes) into solid products with the necessary level of moisture in numerous industries, including the chemical, pharmaceutical, mineral, and food industries. Spray drying has contributed to the drying of fluids and the encapsulation & microencapsulation of essential foods and useful nutraceutical components.

However, you can determine the most serious global difficulties associated with spray drying powders and the corresponding remedies. These include poor powder quality and consistency, facial hair, maintenance wear and tear, substandard hygiene, and safety.

Low-Quality Powder and Powder Consistency

Product Accumulation

The dryer layout can cause condensation, broader spray angles, or a powder formulation. However in most situations, it is the nozzle design. The burnt particle deposits can compromise on the powder quality as it causes product accumulation in the chamber.

Wear-Part Misalignments

Traditional nozzle designs feature misalignments between the swirl chamber and orifice. By this way, decentralised components result in variable spray performance and impact the powder's quality throughout all drying operations.

Solution

Flat Cap Profile

The flat cap design has a reduced outer face profile, which considerably reduces buildup. According to research conducted in New Zealand, chambers utilising proper technology create powders with 20 per cent less buildup than any other laboratory spray dryer nozzle. People can accomplish this by inserting the O-rings into the disc orifice.

Concentric clasp technology

Increasing powder performance and uniformity. Pressure – flow consistency – result predictability. In deed, the nozzles align wear elements to create a uniform spray pattern throughout all lance sets.

Low Productivity

Problem

Nozzle Bearding

The dryer configuration may cause bearding, greater spray angles, and powder formulation, but it is primarily attributable to poor nozzle design. This increases the frequency of cleaning, which delays manufacturing. Production halts for cleaning & short run times contribute significantly to the low productivity of dryers.

Solution

Flat Cap Profile

The design of the flat top drastically reduces facial hair growth. This means fewer dryers will need to be shut down for cleaning, resulting in increased output. Reduced buildup slows the bearding process, allowing nozzles to operate longer. The system has a longer runtime! Moving the O-rings inside the wear section aids in reaching this objective.

Maintaining High Hygiene Standards

Design flaw in the nozzle's O-ring groove – Problem

The o-ring groove within the cap of conventional spray nozzles makes cleaning them difficult. Conventional cap chamber designs have tight, inaccessible corners that harbour inaccessible pollutants.

Hygiene & Clean Easy Nozzle – Solution

With a relatively smooth profile, the spray dry industries may now reach a new degree of cleanliness with greater ease. The caps are meant to be easier to clean and to deliver more hygienic outcomes. Additionally, a smooth bore design increases cleanliness and sanitation. Professional laboratory spray dryer suppliers can help you in procuring the best equipment.

High Production Costs

Problem

Outdated Disassembly Procedures

It may be difficult to disassemble cooked nozzles. The use of impact instruments such as hammers results in significant breakage & wear part prices.

Damaged Threads and Unprotected Sealing Surfaces

Normal thread systems are too delicate to resist normal impact damage. In addition, unprotected sealing faces are easily broken during handling, necessitating the cutting and rewelding of nozzle bodies.

Solution

Simple disassembly

The disassembly process does not require impact instruments to strike wear parts. This reduces breakage and operational expenses.

Heavy-Duty Threads and Robust Cap Protection Skirts

The nozzles are built with heavy-duty threads and a particular shape that is highly resistant to regular physical damage while lance handling. The nozzles also include a seal face protecting the skirt. This design of sturdy cap protection skirt prevents o-ring seal groove damage.

Safety Concerns

Problem

Due to assembly, radial o-ring ripping has occurred.

Conventional radial seal systems are susceptible to o-ring drag and tearing while assembling, compromising sealing integrity.

Solution

Spray Dry Axial Seal Construction

The Axial o-ring design could only reach the sealing face when the cap is completely engaged with the body. The absence of pulling & tearing during assembly reduces the likelihood of leaking.

o Decrease nozzle buildup (bearding) and obtain longer run times

o Enhance powder quality by minimising burnt particles

· Improve hygiene with cap internals that is simple to clean

o Increase wear part durability and eliminate failures

· Save money and reduce operational costs by up to 60%

Are you looking for reliable laboratory spray dryer manufacturers?

Get in touch with us!

Head of Innovation

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Benenatis mauris. Vestibulum ante ipsum primis in industry, logistics, finance, business orci ultrices venenatis mauris.

Marketing

92%

Marketing

82%