Spray Drying solutions for R & D and Production

Mumbai, Maharashtra

Monday to Saturday

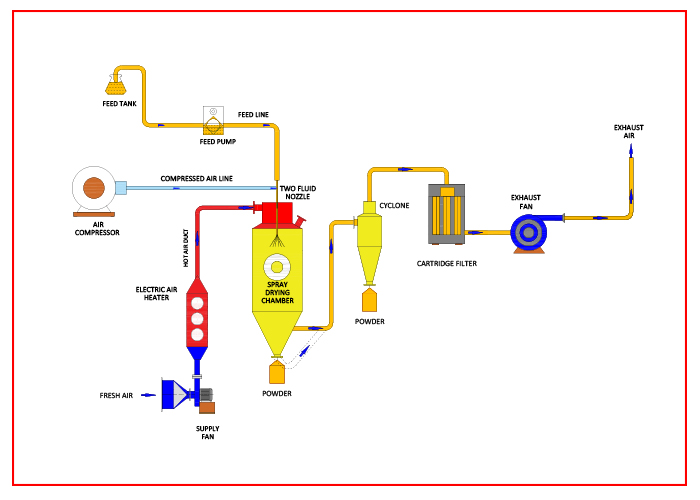

The spray drying process of a lab spray dryer is a method of structured technology applied to material drying. Atomization of the substance happens in the drying chamber, and when it comes into contact with hot air. As a result, the moisture evaporates quickly, yielding the drying product. The method can effectively dry the solution into powder form. Ultimately, this saves evaporation, crushing, and other processes. The spray granulation dryer is essential in the thermal ceramic production process. Still, it is more expensive, has a more complicated composition, and is difficult to use and maintain.

Spray drying is the process of converting wet substances into dried powders. An explosion is possible whenever there is dust or powder in the spray drying machine. As a result, safety measures when using a laboratory spray dryer becomes essential before the operation.

The common use of the lab spray dryer is the production of microcapsules or microspheres for drug delivery systems. Spray drying is a well-known particle production method that transforms the fluid material into dried particles. The process utilizes a gaseous hot drying medium. Certainly, it comes with many advantages for the fabrication of medical devices. Below is the various stages of the spray-drying process's mechanism.

Firstly, atomisation is a droplet-to-particle conversion process. At the same time particle collection also happens here. The process focuses on various available atomisers, the drying kinetics and drying chamber configuration. Additionally it considers the efficiency of collection devices. Several factors influence the final properties of the dried products. This includes the spray dryer design, feed characteristics, and processing parameters. Above all, the effects of these variables optimises both the spray-drying process and properties. The manufacturing process in producing dried particles(submicron-to-micron range) benefits a wide range of applications. Some common sectors include the food, polymeric, chemical, pharmaceutical, biotechnology, and medical industries.

When using organic solvents (such as xylene, ethanol, and so on), keep the oxygen concentration below 5%. Otherwise, the solvents will burn and possibly explode.

Ensure not to touch the spray dryer's rotating parts while it is running. Especially be careful with parts like the atomisation plate, atomiser, belt, and fan blade. The spray dryer's surface temperature is high. Especially while the machine is running or for a short time after shutdown. Hence, stay away from the cyclone, atomiser, and observation windows, among other things.

Be cautious when opening and closing the spray dryer door. Especially be careful when assembling or disassembling the parts like air duct, cyclone separator, and atomiser.

Aggregates will show up in some spray granulation dryers. Most of the time it is due to the improper operation, or if the spray dryer is running for an extended period. At this point, you must shut down the machine and clean it. Firstly, when you clean, leave the door open. Sweep the aggregate in the funnel-shaped bottom with a long broom. Later, when opening the discharge valve, and when the freezer turns on,, ensure to rinse the boiling tower with tap water.

Spray dryer maintenance — requires inspection after 600 hours of operation

All the devices require inspection and maintenance after 600 hours of operation. Ensure to check filters, pipes, valves, nozzles, and other feeding system components to see if it clogs. In that case, clean them regularly, and monitor nozzle wear so that you can replace it when it wears out. In the same way, check to see if the feeding pump is leaking, if the pressure is normal, if the oil level is average, and so on. Check the shaft and bearing of the dryer fan to see if there is enough oil to generate heat. In case of any vibration, and noise. Clean the three filters of the oil pump, oil pipe, and oil nozzle if necessary.

Spray dryer maintenance—in case of emergency

In an emergency, shut down the machine immediately. Firstly, turn off the the blower and material pump. If the power goes out unexpectedly, start the gas engine to cool the tower naturally. Later, open the drain valve to drain the slurry in the pipeline and clean the spray dryer.

Are you looking for a reliable lab spray dryer?

Get in touch with us!

Head of Innovation

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Benenatis mauris. Vestibulum ante ipsum primis in industry, logistics, finance, business orci ultrices venenatis mauris.

Marketing

92%

Marketing

82%