Spray Drying solutions for R & D and Production

Mumbai, Maharashtra

Monday to Saturday

In the pharmaceutical industry, it is important to ensure that you manufacture products efficiently and effectively.

At the same time, it is crucial to produce high-quality products while also minimising waste. This can be difficult to do when using a spray dryer. You must consider several things to optimize the efficiency of a spray dryer in the pharmaceutical industry.

You also need to ensure that you manufacture products efficiently and effectively. One of the most important tools in this industry is the spray dryer. We will discuss how to increase the efficiency of a spray dryer in the pharmaceutical industry.

To create a quality powder product, it is important to have an efficient spray dryer. Pharmaceutical industry makes use of spray drying to develop powders from solutions and suspensions. The process can create various powder products, including active pharmaceutical ingredients (APIs), excipients, and food ingredients.

A lab spray dryer is a machine that converts liquid or moist solid substances into powder through a high-velocity gas stream. The process is also known as atomisation, precipitation, and aerosolization.

Spray drying can be done in different ways:

- in batch mode;

- in continuous mode;

- with an intermittent operation (in which the product is dried for some time and then rewetted);

- with recycling of the heat from the hot gas stream.

A laboratory spray dryer can be energy efficient and save energy by using a vacuum pump, which removes moisture from the air before it enters the system. When combined with heat recovery and an exhaust gas scrubber, this system can reduce its energy consumption by up to 50%.

Several factors can affect the efficiency of a lab spray dryer. The nozzle plays a significant role in determining droplet size and distribution. Atomisation air pressure determines the amount of liquid that transforms into dry powder. Another way to improve the efficiency of a spray dryer in this industry is by optimising the drying process.

To optimise the performance of a laboratory spray dryer, it is necessary to consider both factors. By optimising these two factors, it is possible to increase efficiency by up to 50%. This can lead to significant savings in time and money for pharmaceutical manufacturers.

If you are looking for ways to improve the efficiency of your spray dryer, contact a professional today. They will be able to provide you with the information and advice that you need to make the most of your equipment.

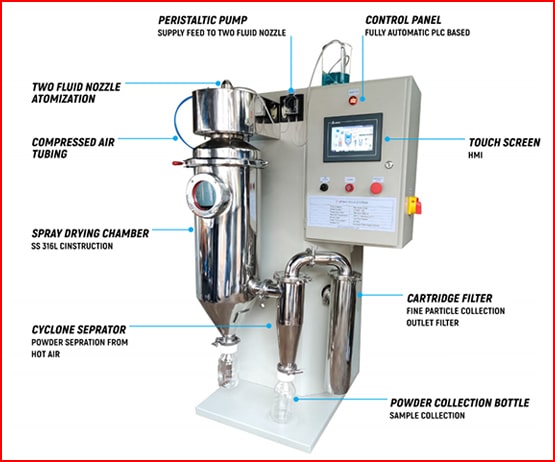

To increase efficiency and reduce energy consumption, it is important to understand the process in a lab spray dryer. A spray dryer is an industrial drying machine that uses hot air to remove moisture from wet materials, such as foodstuffs, textiles, and pharmaceuticals. The material enters through an inlet on one side and exits on the other side as a dried product heated by hot air blown over it by a fan. Spray drying is typically faster than other drying methods because heat transfer occurs at a higher rate than other methods. Electric resistance heating is the most common heat source in modern spray dryers.

The dryer consists of a fan on one side and the heating surface on the other. The material is heated with hot air, and then forced through a nozzle at high speed. This causes it to leave behind any water as mist or vapour. Setting up the nozzles to spray the material so that drying happens uniformly; and will not clog up the nozzle. However, Spray dryers typically use hopper systems to feed materials into the machine on one side of the heating surface and collection systems to collect the dried products on the other. A manual or automatic process regulates the quantity of material entering a single batch. Dryer nozzles are fully automated, using computerised controls and sensors.

What are the important components in the spray dryer that determine the efficiency?

There are several important components in a spray dryer that determine its efficiency. Moreover, the nozzle is responsible for creating the droplets that gets dry. The pump provides pressure to push the liquid through the system, and the atomiser breaks up the liquid into small droplets. If these components are not working correctly, it can reduce the system's efficiency.

Are you looking for reliable spray dryer manufacturers in india?

Get in touch with us!

Head of Innovation

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Benenatis mauris. Vestibulum ante ipsum primis in industry, logistics, finance, business orci ultrices venenatis mauris.

Marketing

92%

Marketing

82%