Spray Drying solutions for R & D and Production

Mumbai, Maharashtra

Monday to Saturday

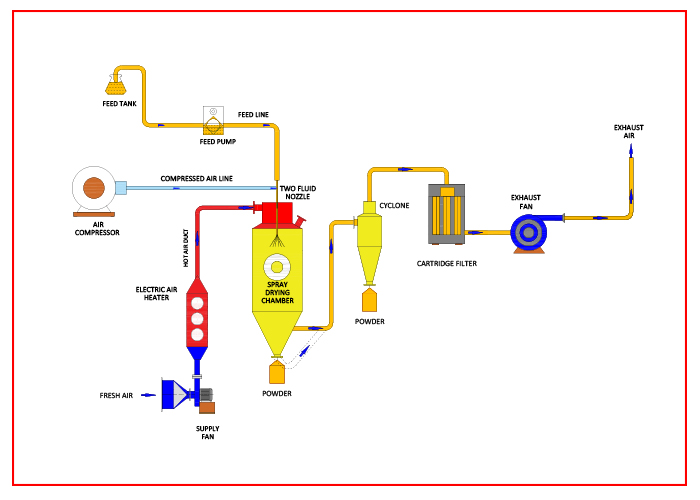

Spray Drying Is The Transformation Of Feed From A Fluid State Into A Dried Particulate Form By Spraying Feed Into Hot Drying Medium.

Spray Drying Technology Is The Most Widely Used Process In Chemical, Minerals, Pharmaceuticals, Food, And Dyestuff Industries For Converting Liquid Solution/Suspension/Slurry/Emulsion Into Powder, Granule, Or Agglomerates.

Head of Innovation

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Benenatis mauris. Vestibulum ante ipsum primis in industry, logistics, finance, business orci ultrices venenatis mauris.

Marketing

92%

Marketing

82%