Spray Drying solutions for R & D and Production

Mumbai, Maharashtra

Monday to Saturday

Spray drying is a process that has gained popularity in the food industry due to its many benefits. The laboratory spray dryer is faster and more efficient than other methods, and it also helps preserve the nutritional value of foods. As the demand for spray-dried foods increases, so does the need for spray-drying equipment.

The food industry equipment market may grow by USD 450 million from 2020 to 2024, at a CAGR of 5%. This growth can be explained by the growing need for healthy, easy-to-find foods and the need for more efficient ways to make things. Spray drying is a key part of many food production lines, so it's important to invest in good equipment.

Spray dryers are used in the food and beverage industries to produce powders and granules, and they are also used in the animal feed industry to produce pellets.

You need to choose a lab spray dryer based on its capacity, the type of product, the throughput you need, how long you want it to dry, etc. People can also select based on its operating pressure ranges and the type of atomisation system it uses.

When selecting a spray dryer, it's important to consider several factors. One of the most important things to look at is how easy it is to use, clean, and set up. After considering the basics, the main focus should be on the functional factors. Equipment that is easy to operate, adjust and develop optimum conditions.

Choosing a drying agent is one of the most important things to know before deciding on the laboratory spray dryer suppliers. Different drying agents have other properties, and it is essential to take this into account when choosing a drying agent.

A drying agent's efficiency largely depends on its particle size distribution. For example, suppose an agent has a larger particle size distribution. In that case, it will have less surface area for evaporation and thus need more time for the water to evaporate from the particles.

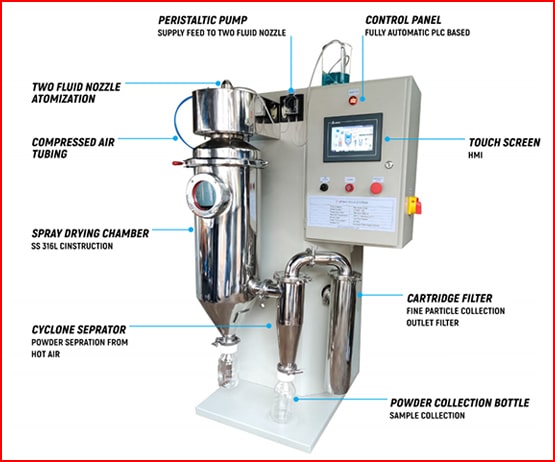

The main functions of the instrument are to control the airflow, temperature, and pump speed. The volume should equate to the pressure from an air compressor. It's easier to control the amount of active pharmaceutical ingredients (API) required for development with this instrument. Additionally, laboratory spray dryer manufacturers can determine the strength and behaviour of the API with this piece of equipment. Finally, people can set the quantity of dry mix formulation required with this machine.

The amount of solids in the active and the amount of encapsulant will determine the size of the batch as a whole. The type of drying gas needed will depend on the solvent used to make the emulsion. The solvent could be air or nitrogen. With this information in mind, one can choose the proper settings for their instrument.

Maintenance tips

Maintenance of spray dryers is also important in preventing explosions. Always keep the following in mind when maintaining your machine: When using a spray dryer, always take the following precautions:

1. Make sure that the area around the machine is clean and free of dust and powder.

2. Inspect the machine regularly for any signs of wear or damage.

3. Do not operate the machine if it is damaged.

4. Always wear proper protective clothing, including a dust mask, when operating the machine.

5. Do not allow anyone else to be in the vicinity while the machine operates.

6. Follow the manufacturer's instructions for proper care and maintenance of the machine.

7. Regularly check for blockages in the nozzle and other machine parts.

Taking these precautions can help prevent accidents and explosions when using a spray dryer. Besides taking these precautions, it is also important to keep the spray dryer in good shape by giving it regular maintenance.

In addition to taking these precautions, it is also important to perform regular maintenance on the spray dryer.

Maintenance after 600 hours of operation

It is important to check on and maintain your spray dryer regularly to ensure it works at its best. After about 600 hours of use, you should check the feeding pump for leaks and look at the filters, valves, pipes, nozzles, and other parts of the feeding system for clogs or other problems. Additionally, check the wear on the nozzle and replace it as needed. You can keep your spray dryer in top condition by taking these proactive steps.

Regular cleaning

It is important to clean your spray dryer to avoid fires and explosions caused by excessive build-up. This will help maintain your product's quality and prevent cross-contamination. Microbial growth can also be a problem if the chamber isn't clean. Regular cleaning will keep your spray dryer running smoothly.

When it comes to spray drying, seasonal variation can have a major impact on performance, and that's why it's important to standardise the incoming air for optimal productivity year-round.

The air's overall moisture limits the dryer's capacity, and the air leaving the chamber should not be very moist. To get the most out of the chamber, it should be run with as much moisture as possible.

Are you looking for reliable spray dryer manufacturers in Mumbai?

Get in touch with us!

Head of Innovation

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Benenatis mauris. Vestibulum ante ipsum primis in industry, logistics, finance, business orci ultrices venenatis mauris.

Marketing

92%

Marketing

82%