Spray Drying solutions for R & D and Production

Mumbai, Maharashtra

Monday to Saturday

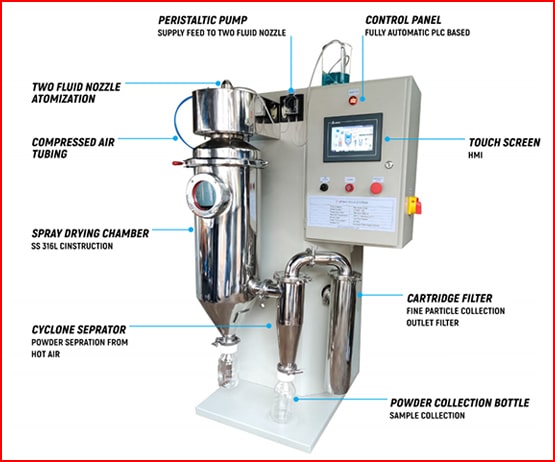

Spray drying is a process in which the liquid is forced into small droplets by a high-velocity jet of hot gas. It is widely used in the pharmaceutical industry to remove water from solutions or powders, but it can also be used for food dehydration.

How Spraying Technology Can Ensure Safe Production of High-Quality Pharmaceutical Products

In the pharmaceutical industry, many cleaning processes must be followed to ensure the quality of products. The process starts with spraying water on the product, cleaning it with chemicals, scrubbing and drying.

Spraying water on products is time-consuming and energy-intensive, resulting in low yields and poor quality. The development of Spray technology makes this process more efficient. It uses a spray nozzle that sprays droplets within seconds instead of a continuous stream of water for better production yields.

Lab spray dryers ensure cleanliness and high-quality pharmaceutical products with less effort than conventional cleaning methods.

The spray technology is applicable in industries where the production yield determines business success. The spray nozzle is a great way to ensure high-quality production because contaminated products can be removed easily with minimal effort. Spraying technology has environmental benefits such as reduced water use, fewer chemicals, and less heat and noise.

Increasing productivity

Spray drying is a process that removes water from a material, leaving behind solids and gases. Spray dryer manufacturers in India follow a process used in pharmaceuticals to reduce the cost of production while increasing productivity.

The use of a Spray dryer increases productivity in many ways

- Spray drying can convert wet granules into powder form, which is easier to handle and store.

- The lab spray dryer can produce more suitable granules for tablets or capsules.

- Spray drying can also produce fine powders; other methods such as freeze-drying or spray chilling may not have been possible.

A laboratory spray dryer is becoming an increasingly popular method for producing powders from wet materials such as pharmaceuticals. The process uses less energy than other methods and has a shorter drying time. It can efficiently reduce production costs and increase productivity.

In the pharmaceutical industry, spray drying is a process that helps to reduce the number of steps, shorten production time, and increase yield. If you are looking for a spray drying technology for your manufacturing process, you should consider the benefits of using it and its time-saving benefits. The primary use of laboratory spray dryers is for the dry powder production of aerosolised drug products such as inhalers, nasal sprays, and creams. It helps in manufacturing tablets, capsules, and modified-release formulations. In pharmaceutical manufacturing, spray drying, an alternative to fluid bed granulation processes, can significantly reduce equipment costs and time.

A spray dryer is a machine that sprays a liquid onto the surface of a product to dry it. It’s used by many industries and companies around the world. The spray dryer is an important piece of machinery for any company or industry that uses it. The type of spray dryer you need will depend on what you are doing with your product. Many factors go into choosing the best product for your company’s needs, but here are some things to consider: How much does it cost? What is its capacity? What type of equipment does it require?

The cost of a spray dryer is one factor in deciding which type of spray dryer you will need. The amount of money that you will be spending on your new equipment is going to depend on the size and features that it has.

The capacity or size of the sprayed product is another factor to consider when selecting a spray dryer. The product's capacity will depend on the size of the drying chamber and how many bags or drums it has. The higher the capacity, the more effective it will be for your company’s needs.

The type of equipment that helps in operating a spray dryer can have an impact on its overall cost. For example, if your new spray dryer involves a lot of maintenance and may be challenging to maintain, you will need a more expensive spray dryer. Although the total cost of the tool is one factor to consider for purchase, it does not necessarily have to be your only consideration.

Are you looking for reliable spray dryer manufacturers in India?

Get in touch with us!

Head of Innovation

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Benenatis mauris. Vestibulum ante ipsum primis in industry, logistics, finance, business orci ultrices venenatis mauris.

Marketing

92%

Marketing

82%