Spray Drying solutions for R & D and Production

Mumbai, Maharashtra

Monday to Saturday

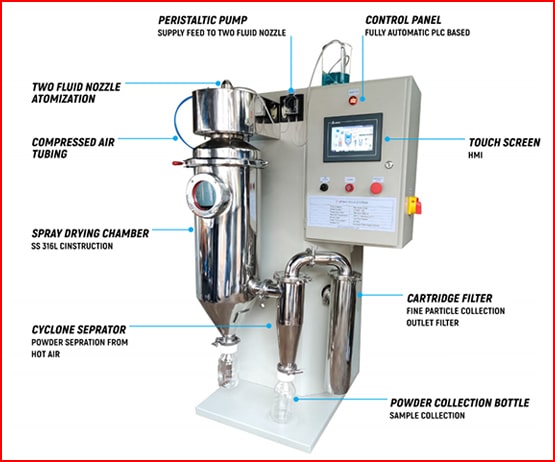

A laboratory spray dryer is a type of drying system used in laboratories to dry liquids to solids. Laboratory spray dryers is highly beneficial for drying small quantities of liquid and can operate with or without compressed air. Many industries including pharmaceuticals, cosmetics, food processing, chemical engineering, and biotechnology make use of laboratory spray dryer. They are also used in research labs to reduce the time it takes to dry liquids and make them solid. The spray dryer consists of a container and a spray nozzle mounted on an axle. The suspension of the container is done from the ceiling, which acts as a wall for the liquid to passively fall into. A fan mounted at the top of the container pulls air upward through the liquid and causes atomisation, which increases the surface area that can be acted upon by evaporation.

A laboratory spray dryer is a device used to produce powders, granules, and fibres. It helps in drying liquids.

A laboratory spray dryer has two main parts: an atomisation chamber and a drying chamber. The atomisation chamber takes liquid material and turns it into droplets that get sprayed into the drying chamber, where the hot air or infrared radiation dries it.

A laboratory spray dryer is beneficial in laboratories for drying small amounts of samples. They are usually constructed with a stainless steel body and designed to use with liquid and powder samples. Laboratory spray dryers can be either batch or continuous-feed machines, often equipped with an electric heating element.

The working process of a laboratory spray dryer includes the following steps:

1) The sample is placed in the drying chamber.

2) It seals off the chamber

3) The heating element switches on

4) The heat causes the sample to evaporate.

5) This evaporation reduces the weight of the sample by anywhere from 30-90%

The drying process is the first thing to consider when designing a lab drying machine. The second thing to consider is the type of material you want to dry. There are two main types of laboratory drying machines: spray dryers and fluidised bed dryers. Spray dryers are better for drying powders and granules, while fluidised bed dryers are better for solids and pellets. If you have a large quantity of liquid samples for drying, then you should use a spray dryer design. If your samples are more solid or powdery, you should use a fluidised bed design instead.

There are three major components to consider to design a lab drying machine: the heat source, the air outlet, and the material nozzle. The heating process is typically happen with electric or natural gas furnaces. The air exiting process happens with a rotary vane or axial flow fan. Also, the design of the material nozzle helps in parallel ports and full flow nozzles. In a spray drying device, it passes the material to dry it through a heated and pressurised stream of water vapour into a heated chamber where it condenses on the walls, leaving the active agent behind. The retention of active agent happens by evaporation in this chamber before spraying out through small holes at the end of the spraying chamber.

If you want to ensure the longevity of your spray dryer, then you must maintain it properly. Spray dryer manufacturers in India suggest few steps before and after you clean the spray dryer.

Several industries use Spray dryers in laboratories and industries for drying various materials. This article will cover the best practices for lab spray dryers used at the lab and in the industry.

Various industries make use of spray dryer to dry various materials, including food, pharmaceuticals, chemicals, and other industrial products. Some laboratories also make use of it to produce test specimens for chemical analysis or as an alternative to oven drying.

The following are some best practices for using spray dryers:

- Keep the nozzle clean

- Use filtered water when available

- Do not overload the hopper with material

- Use a fan or vacuum to improve airflow

- Make sure that you have enough power supply

A laboratory spray dryer is a type of drying system used in laboratories to dry liquids to solids.

Are you looking for reliable industrial laboratory spray dryer manufacturers?

Get in touch with us!

Head of Innovation

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Benenatis mauris. Vestibulum ante ipsum primis in industry, logistics, finance, business orci ultrices venenatis mauris.

Marketing

92%

Marketing

82%