Spray Drying solutions for R & D and Production

Mumbai, Maharashtra

Monday to Saturday

Spray drying is a process of rapid drying a liquid or slurry into a dry powder with a hot gas. Almost every sector uses spray dryers, including medicines, detergents, paint, pigments, food, dairy, mining and minerals. They can dry at speeds ranging from a few pounds to many tonnes per hour, although the higher rates are more expensive to run.

The input material is atomized or sprayed into the drying chamber in tiny droplets in spray dryers. They are versatile continuous processing equipment. Traditional vertical arrangements are divided into two types based on how the feed is introduced. The first, tall-form dryers, atomize the feed using nozzles. Due to the nozzle's narrow spray angle and the relative velocity of the droplets, they require a tall drying chamber with a tiny diameter to achieve drying.

The second group utilizes rotary disc atomizers or centrifugal atomizers to create the spray. The rotary atomizer spray angle is flat, necessitating a big diameter tower with a low height. Others include box spray dryers, which use the same principles but remove the product from the drier housing through a conveyor, and pulse-combustion spray dryers.

Spray dryers consist of a large round drying chamber and a tiny cone-shaped base made of stain-free steel, with a drying chamber size ranging from 2.5 to 9 meters and an elevation of 25 meters or more. The spray disc atomizer is approximately 300mm in diameter and rotates at a rate of 3,000 to 50,000 times per minute.

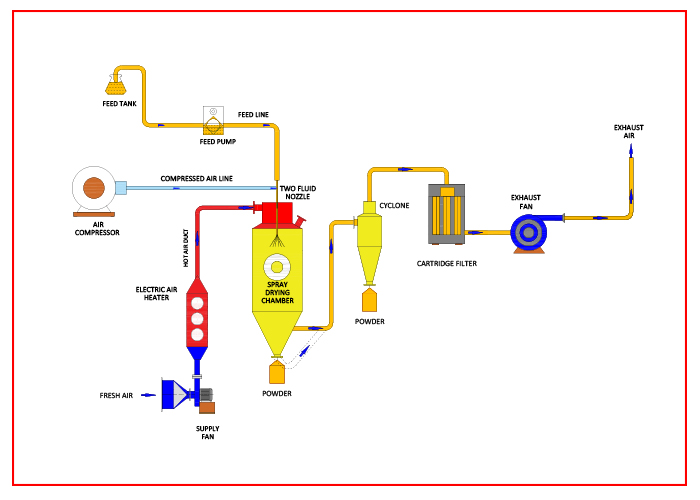

Spray drying is a one-step steady-state system process that uses fluid atomization to create droplets dried to precise pieces when moved to a heated drying form. A feed pump, atomizer, air heating unit, air dispenser, drying chamber, and systems for exhaust air purification and powder recovery/separator make up a spray dryer.

In the spray dryer, the liquid is atomized into tiny droplets and flung radially into a moving stream of hot gas. The temperature of the droplets is immediately raised, and likewise, lovely droplets are quickly dried by round pieces. Before the droplets reach the dryer's wall surface. In general, this process takes a few seconds to complete.

The fluid to be evaporated is sprayed via moisture in the spray dryer. The minute drops are readily evaporated and transformed into solid particles that reach the chamber's bottom. The vapors are pumped to a separator, which separates and collects excellent drying pieces that have been mixed in with the steam.

Spray drying turns a liquid into a powder with specific qualities. Powder properties such as moisture content, particle size, and density can be controlled to achieve desired values. Its versatility in customizing powder characteristics, the gentleness of the process, and low cost compared to alternatives like freeze-drying has led to its widespread use in cosmetics, fine chemicals, detergents, polymers, excipients, and medicines.

Spray-drying has several uses in the pharmaceutical and drug delivery fields, only a few of which are discussed here.

1. Excipient production: Spray-drying can be used to make pharmaceutical excipients with specific characteristics. Directly compressible powders in solid dosage forms like tablets, for example, have better compressibility.

2. Encapsulation: Innovative controlled drug delivery systems are generated using a unique spray-drying approach in the microencapsulation of antiretroviral drugs in olibanum gum resin. The encapsulation of rifampicin in olibanum gum resin also uses spray drying.

3. Enhancing bioavailability: Poorly soluble medications can benefit from spray drying to improve their solubility and dissolving rate. Typically, this occurs due to pharmacological inclusion complexes or the generation of solid dispersions.

4. Dry powder inhalers: Spray drying is an excellent approach for fabricating dry powder inhaler formulations because the process parameters may readily manage particle size distribution and residual moisture content of the spray-dried powders. In rats, systemic pulmonary distribution of rifampicin was shown to have higher absorption and absolute bioavailability than oral treatment.

5. Drying of heat-sensitive materials: Due to the cooling effect generated by the flash solvent evaporation, spray-drying of heat-sensitive materials is possible. As a result, the actual temperature of the dried product is much lower than the drying air's exit temperature. Due to the higher inlet drying air temperature, the decreased residual moisture content of the spray-dried powder gave good storage qualities, albeit more significant protein inactivation occurred.

Takeaway

Spray drying is a flexible pharmaceutical production approach since it employs a one-step procedure for powder creation and drying. Spray drying is used in the pharmaceutical and biotech industries for microencapsulation, granulation, and complex products, and it is also utilized to modify biopharmaceutical characteristics.

Head of Innovation

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Benenatis mauris. Vestibulum ante ipsum primis in industry, logistics, finance, business orci ultrices venenatis mauris.

Marketing

92%

Marketing

82%