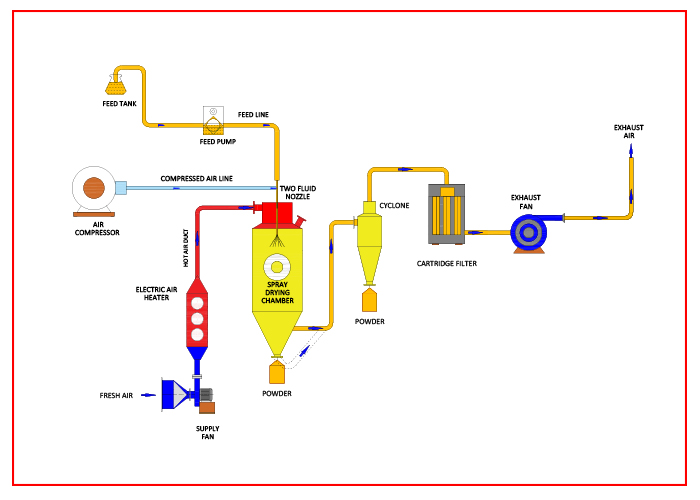

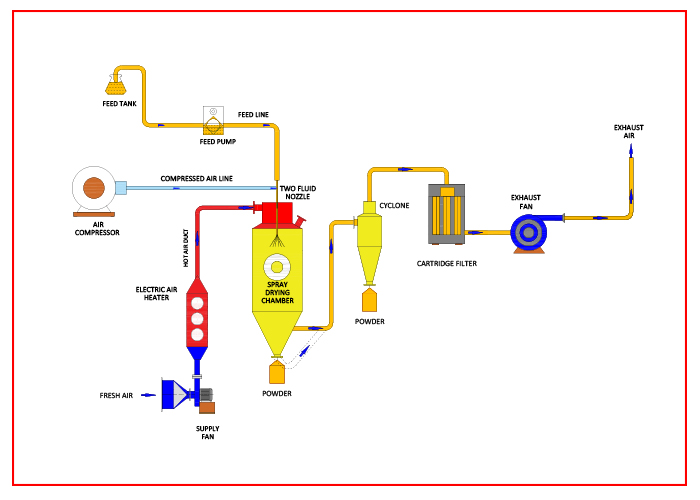

Maintaining your

laboratory spray dryer is essential for keeping it running at peak efficiency. If you neglect to perform routine maintenance, the dryer may not operate correctly and could even break down. In this blog post, we will guide you on how to maintain your industrial spray dryer properly. By following these tips, you can ensure your dryer runs smoothly and efficiently.

Applications for industrial spray dryers

It is essential to consider multiple variables while selecting a spray dryer. One of the most significant factors to consider when purchasing a spray dryer is the convenience of operation (whether or not we can control the particle size), setup, and cleaning requirements. After the fundamentals have been addressed, it is mandatory to consider the functional component. The condition is favourable for the simple equipment to use, change, and create optimal conditions.

The following are the primary functions that the instrument should allow you to control:

You may adjust the airflow, temperature, and pump speed.

The volume should be equal to the pressure generated by an air compressor.

The required quantity of Active Pharmaceutical Ingredient (API) for development

The API's strength and behaviour

The required amount of dry mix formulation

The amount of encapsulant and the solid content of the activity will determine the overall batch size.

The selection of drying gas type depends on the solvent helpful in creating the emulsion, which could be either air or nitrogen.

Maintenance Tips For Laboratory Spray Dryer

The first step to maintaining your

lab spray dryer is regularly cleaning the air filter. A dirty air filter can restrict airflow and cause the dryer to overheat. To clean the air filter, remove it from the dryer and wash it with soap and water. Once it is clean, replace it in the dryer. It is also important to clean the inside of the dryer regularly. It can be done by removing any dust or debris accumulated on the interior surfaces.

Ensure to optimise

The three most common ways to optimise your lab spray dryer are adjusting inlet, exit, and feed temperatures. Furthermore, it can increase the quality of the product and avoid production losses like those caused by CIP (Clean-In-Place). Finally, it's necessary for the winter season because there is more moisture than at other times throughout the year.

Level of wear and tear

Another key component of proper maintenance is keeping an eye on your industrial spray dryer's level of wear and tear. Over time, components will wear out and need replacement. It is its heating element, which is one of the most important components. If you notice the heating element is not working, it is time to replace it.

Regular maintenance will not only prolong the life of your dryer but also improve its efficiency. So, be sure to keep up with routine maintenance and inspections! By following these simple tips, you can ensure that your laboratory spray dryer remains in good working condition for many years.

Are you looking for reliable

spray dryer manufacturers in India?

Get in touch with us!