Spray Drying solutions for R & D and Production

Mumbai, Maharashtra

Monday to Saturday

You know that many different technologies can benefit your business if you are in the industrial sector. One of those technologies is spray drying. It is one efficient way to improve your industrial process. We will discuss the industrial applications of spray dryers and how they can benefit your business.

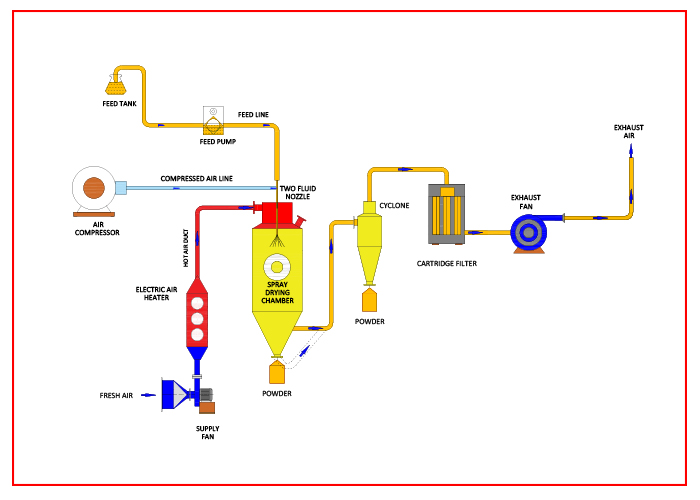

Spray drying involves atomising a liquid into tiny droplets and then quickly drying them with hot air. However, people can use the process to dry anything from food products to chemicals.

The food industry is one of spray dryers' most common industrial applications. Spray drying is useful in producing dry milk products, eggs, and coffee. The process can also help to create instant soups and sauces.

Another common use for spray dryers is in the pharmaceutical industry. Spray drying helps create powders from liquids. The tablets or capsules can

In the chemical industry, spray dryers are beneficial in creating catalysts and other chemicals. Creating pigments and dyes uses this process.

Spray drying is a versatile technology that is useful in producing various powders with different properties. Operators can tailor the powder to meet the customer's specific needs by, for example, controlling the particle size distribution or changing the composition of the powder. With over 50 years of experience designing and manufacturing spray dryers, GEA is a world leader in this technology. We offer a wide range of spray dryers for different industries and applications. Our experts can help you find the right solution for your specific needs.

There are many reasons why spray drying is such a popular choice for industrial applications. Some of the advantages of spray drying include:

The processes are very versatile and beneficial in producing powders with a wide range of properties.

Industrial spray dryers can handle a wide range of feedstock viscosities, from light liquids to heavy pastes.

Spray drying is the most effective way to achieve uniform particle size and moisture content in your dried product.

Industrial spray dryers can operate at a wide range of temperatures, allowing you to tailor the drying process to your specific needs.

Spray drying is a fast and efficient way to dry large quantities of material in a short period.

The powder produced by spray drying is very fine and has a large surface area, which makes it ideal for many applications.

You can easily scale up or slow down the process to meet the customer's needs.

If you are looking for an effective way to dry your product, spray drying may be the right solution.

Head of Innovation

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Benenatis mauris. Vestibulum ante ipsum primis in industry, logistics, finance, business orci ultrices venenatis mauris.

Marketing

92%

Marketing

82%