Spray Drying solutions for R & D and Production

Mumbai, Maharashtra

Monday to Saturday

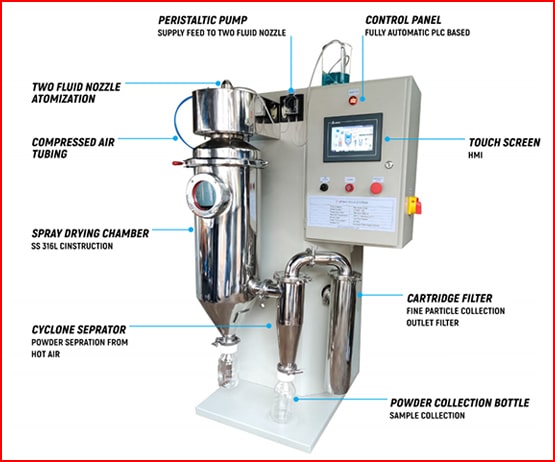

Spray drying is a popular method of particle manufacturing that entails the transformation of a fluid substance into dried particles using a gaseous hot drying medium, with obvious benefits for medical device creation. Manufacturing microspheres and microcapsules for drug delivery systems are relatively prevalent. In industrial production, the lab spray dryer is presently the most extensively utilised lab spray dryer. The material liquid is pumped via the filter to the top of the dryer's high-speed spinning centrifugal atomising plate, quickly blasted into very fine mist droplets. After coming into touch with hot air, the misty droplets swiftly evaporate. After passing through the bag dust chamber or water film dust collector, the final powder is recovered by the barrel at the base of the cyclone separator, and the leftover waste gas is expelled.

The liquid forms a thin film on the dispersion plate's surface and is thrown out at a high rate around the circle. The atomisation effect is influenced by the circular, linear speed and feeding rate and the liquid's physical and chemical qualities.

Read on to know more about the applications of Laboratory Spray Dryer

In an industry that is becoming increasingly demanding in terms of productivity and profitability, critical decisions must be made from time to time. One such debate is whether to use spray drying or freeze-drying when working to develop a production process.

Spray drying is a much faster and simple procedure that involves converting a liquid formulation to a dry powder in a single step. The solution is atomised into fine droplets immediately dried in a vast chamber with a heated gas. A cyclone is used to collect the dry particles that result.

The laboratory spray dryer is proven to be effective in preserving the below inherent product characteristics while processing.

● Efficacy

● Taste

● Smell/color

● Nutritional value found in food.

● Protein Degeneration

The spray-drying mechanism works by removing moisture from the feed product by exposing it to a hot environment. Three primary steps can be identified in the process that includes atomisation, droplet-to-particle conversion and particle collection. The liquid supply is first fed through an atomiser, which breaks it up into a spray of small droplets. The droplets are then expelled into a drying gas chamber, where moisture evaporation occurs, resulting in dry particles. Finally, the dried particles are removed from the drying media and collected using an appropriate apparatus in a tank. All of these stages and the processing conditions significantly impact the spray-drying mechanism's yield and the final particle qualities.

The lab spray dryer has a wide range of applications.

The spray drying technique was initially restricted to producing milk powder, cosmetics, detergents, egg powder, and other items over more than a century of development. It has been widely employed in the chemical, biological, food, pharmaceutical industries, ceramics, and other industries in manufacturing ultrafine powder and nano powder as research and application have progressed.

1. Chemical Industry: Battery raw materials, compound fertilizers, dye intermediates, sulfuric acid, amino acids, white carbon black, and other chemical products

2. Biology: Bacterial cells, proteins, peptides, enzyme preparations, or other physiologically active materials that are heat sensitive;

3. Resins: AB, urea-formaldehyde resin, phenolic resin, polyethylene, polyvinyl chloride, and other resins are examples.

4. Food: fat-rich milk powder, animal blood meal, muscle protein, egg white and whole egg powder, oats, chicken juice, instant coffee, tea, soybeans, protein, and other similar items.

5. Ceramics: Alumina, magnesium oxide, ceramic tile materials, talc, and other similar products

6. Sugar: Corn syrup, glucose, corn starch, maltose, pectin, potassium sorbate, and so on

7. Chinese medicine extracts: Chinese medicine formula granules, Chinese medicine extracts, solid oral preparations, and some popular Chinese medicine forms. A lab spray dryer is commonly used in the pharmaceutical industry. Drying is crucial in pharmaceutical manufacturing, particularly in the creation of traditional Chinese medicine. The completed result of a spray-dried pharmaceutical has a high level of uniformity. The chemical fluid is sprayed into an atomized dispersion with steady stirring in a lab spray dryer, and the drying is completed instantaneously, resulting in higher homogeneity.

The lab spray dryer in the pharmaceutical industry has the following characteristics:

The final product has good fluidity, looseness, and solubility. During spray drying, the water vaporizes quickly, resulting in small particle size, good fluidity, and flat tablets. When water comes into contact with the particles, it is easier to enter the interior of the particles, making it easier for the drug to dissolve. Hence, when the split dose is packaged, the recommended dose is more precise.

Simplify the manufacturing process. Spray drying can combine concentration and drying in a single step, and the drying time is comparatively short, allowing the heat-sensitive medication to maintain its efficacy.

A closed spray environment prevents bacteria from contaminating the drug and reduces dust pollution in the workshop.

Are you looking for professional spray dryers manufacturers in Mumbai?

Get in touch with us!

Head of Innovation

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Benenatis mauris. Vestibulum ante ipsum primis in industry, logistics, finance, business orci ultrices venenatis mauris.

Marketing

92%

Marketing

82%