Spray Drying solutions for R & D and Production

Mumbai, Maharashtra

Monday to Saturday

Pharma businesses face constant pressure to launch new medications as soon as possible. This means that they need efficient and reliable manufacturing processes, and a laboratory spray dryer can play an important role in this. In this article, we will discuss how laboratory spray dryers can help the pharma industry with their operations, and we will explore some of these machines' benefits. One of the main steps in the manufacturing process is drying, which removes moisture from the product and prevents microbial growth. Spray drying is a common method used in the pharma industry, and laboratory spray dryers are essential for optimising this process. One way to optimise operations is through a laboratory spray dryer. Industrial spray dryers manufacturers in Mumbai offer various product ranges that can help produce powders, granules, and other solid forms of drugs. Furthermore, it also helps in testing different formulations and process parameters.

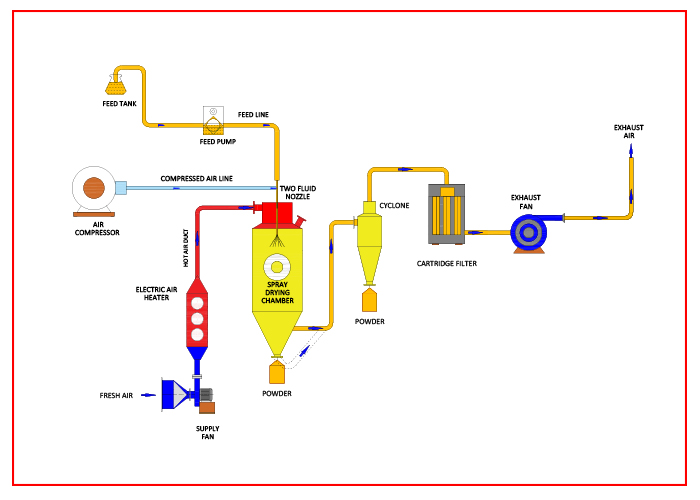

Spray drying is a process where liquid or slurry is sprayed into a hot air stream, which evaporates the water or solvent, leaving a dry powder behind. The advantages of spray drying over other drying methods include its ability to produce a dry powder with a consistent particle size distribution and preserve heat-sensitive ingredients.

Moreover, it is a fast and efficient way to dry products, and the process can be easily controlled to produce a uniform product with consistent quality. Additionally, spray drying allows for a wide range of product formulations, including those with sensitive ingredients that cannot be dried using other methods. Laboratory spray dryer is also less likely to cause product degradation than other drying methods, making them an ideal choice for many pharmaceutical applications.

One of the main advantages of using a lab spray dryer is that it can help reduce the time it takes to produce a new drug. It is because these machines can quickly and easily turn liquids into powders, which is helpful in the manufacturing process. This can save a lot of time, as well as money, for pharma companies who are looking to bring new drugs to market quickly.

Another benefit of using laboratory spray dryers is that they can help to improve the quality of the finished product. These machines provide a more controlled drying environment, which means there is less chance of contamination or errors occurring during the process. It can lead to a higher quality finished product, which is more likely to be successful when it reaches the market.

Overall, there are many benefits that lab spray dryer can offer the pharma industry. These machines can save time and money during the manufacturing process and improve the quality of the finished product. If you are looking for a way to improve your manufacturing processes, then consider investing in one of these machines.

Spray dryer manufacturers in India develop and optimise the spray dryer for each specific product. They allow manufacturers to experiment with various variables, such as air flow rate, inlet air temperature, and atomiser rotation speed, to find the best conditions for that product. This is essential for ensuring that the final product meets all quality specifications.

In addition, laboratory spray dryers help in testing new formulations before they scale up to production volumes. This allows manufacturers to make formulation changes early on without incurring significant costs.

Finally, laboratory spray dryers can be used to troubleshoot production issues. By duplicating production conditions in the lab, manufacturers can identify problems and make necessary changes before they impact large batches of the finished product.

Laboratory spray dryers play an important role in helping pharmaceutical companies meet cGMP guidelines. They are essential for developing and optimising the spray drying process, testing new formulations, and troubleshooting production issues. When selecting a laboratory spray dryer, it is important to choose one that is easy to operate and maintain and offers extensive data logging capabilities so that you can track your experiments and replicate your results over time.

Are you looking for industrial spray dryers manufacturers in Mumbai?

Get in touch with us!

Head of Innovation

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Benenatis mauris. Vestibulum ante ipsum primis in industry, logistics, finance, business orci ultrices venenatis mauris.

Marketing

92%

Marketing

82%