A lab spray dryer is helpful in converting liquid solutions into granules or powder form. The process of spray drying involves atomising a liquid solution into small droplets that dry when it comes in contact with hot air. The result is a free-flowing powder that can be easily packaged and stored.

The advantages of spray drying over other methods include the ability to produce a consistent product with uniform particle size and the fact that it is a relatively quick process. In addition, spray drying is beneficial to dry heat-sensitive materials that would get affected by other methods, such as tensile strength.

Spray dryer – Overview

In a

laboratory spray dryer the process of converting liquid into powder or granules occurs in three primary stages: atomisation, drying, and collection. Atomisation is the process of breaking up the liquid into tiny droplets. They are then heated and dried in the second stage. In the final stage, collection is done as powder or granules.

The size of droplets is important in determining the final product. With the proper liquid atomisation process, the powder will be clumpy and easy to use. The type of liquid affects the outcome. For example, liquids with high-fat content are more difficult to dry and result in a lower-quality product.

How It Works

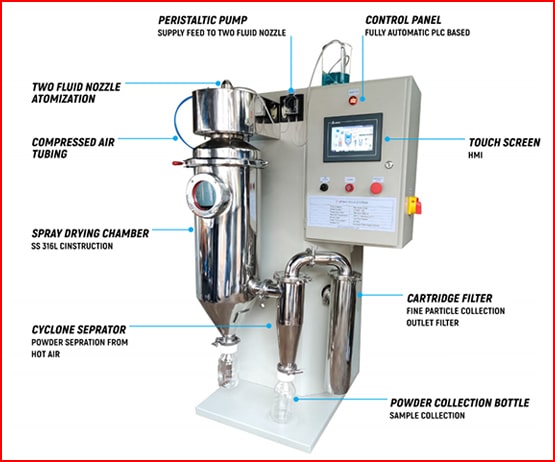

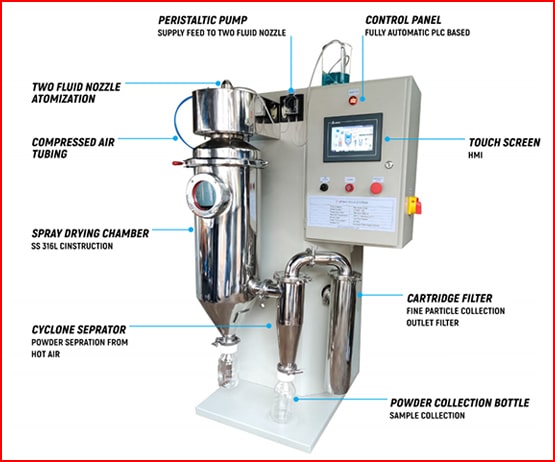

A lab spray dryer consists of three main parts: a chamber where the drying takes place, an atomiser to create the small droplets, and a hot air system to provide the necessary heat.

The atomiser can be either mechanical or air-assisted. The liquid solution is fed into the atomiser, where it gets broken into small droplets. The drying chamber carries the droplets on a stream of hot air. As they come into contact with the hot air, they evaporate and form small powder particles.

The Atomization Process

The pumping of liquid happens through a nozzle at high pressure for the atomisation process to work. The liquid is then broken up into small droplets by the nozzle. The hot gas helps in drying these droplets, which passes through the chamber. The size of the nozzle and the pressure at which the liquid is pumped determines the size of the droplet.

The Drying Process

The gas's temperature determines the drying rate and the airflow rate. During the drying process, the droplets are heated by the hot gas and lose their water content. The water vapour is then removed from the chamber by an exhaust fan.

The finished powder is then discharged from the chamber and collected for packaging. The amount of time it takes for the liquid to convert into powder will depend on factors such as the type of liquid being dried, the amount of water in the solution, and the temperature of the air within the chamber.

Takeaway

A laboratory spray dryer can provide years of service with proper care and maintenance. When selecting a laboratory spray dryer, it is important to consider the intended use of the final product. It will help determine the proper size and type of dryer for your needs.

A lab spray dryer is a versatile piece of equipment that helps create various products in granule or powder form. The process is relatively quick and produces a consistent product with uniform particle size. In addition, spray drying helps in drying heat-sensitive materials that other methods would damage.

Are you looking for reliable spray dryer manufacturers? Get in touch with us