Maintaining your laboratory spray dryer is key to ensuring it runs smoothly and lasts for a long time. Here are some tips on how to do just that!

Top optimisation tips

Optimisation

The spray dryer can be optimised using one of three approaches. The optimization improves the final product's quality and yield. The temperatures at the inlet, exit, and feed can change. Second, optimisation is required to avoid production losses caused by Clean in Place (CIP). Finally, spray dryers perform better because the moisture content in the ambient air is higher in the winter. In a study published in Trends in Food Science & Technology, the response surface technique proves to be the best appropriate tool for optimising spray drying conditions.

Improving the capability

You can determine the

lab spray dryer capacity by the amount of water evaporated by it at the time of wet product loading. It is essential to raise the temperature gradient between the input and exit for optimal evaporation.

The retractable design of a CIP nozzle valve

Even though higher inlet temperatures improve energy efficiency, they do not function at excessively high intake temperatures. Because a specific output temperature may result in buildup in spray dryer vessels, the product cannot be denatured, burned, or deficient in nutrients or desirable characteristics.

Increased run time

A good optimal production should run on a well-planned schedule with minimal or no downtime. A feed system that constantly switches between goods and batches must clean regularly. On the other hand, regular monitoring of the spray drying for allergens and cleaning between allergen manufacturing batches is important.

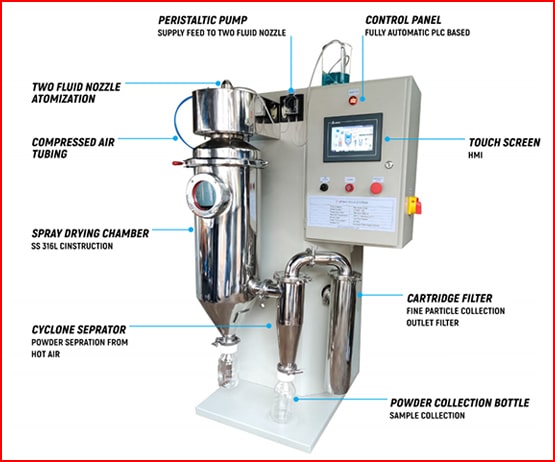

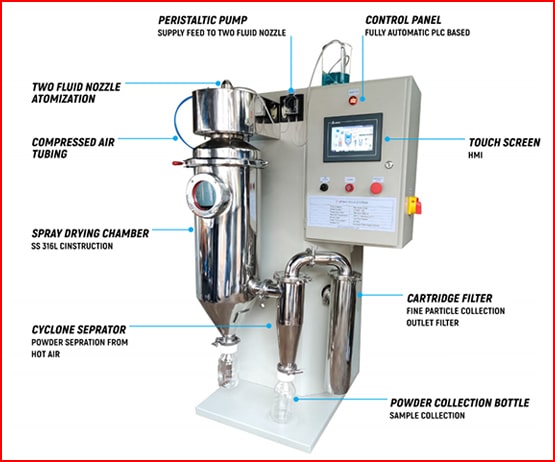

Laboratory spray dryer with two full-capacity feeds became available, making them perfect for automated nozzle systems. You can use a rotary or nozzle to generate an atomizer, and another nozzle when turning off one feed system

Cleaning

Daily cleaning is essential to prevent a fire or explosion. Cross-contamination can lead to quality difficulties, making it difficult for you to keep up with production standards! In addition, daily maintenance tasks are necessary because otherwise, a build-up occurs that causes problems like cross-contamination and 1986 technological issues not being able to fix them immediately when they arise - this way, we are always on top of our game at all times.

Environmental factors

Seasonal variations, as previously noted, have a considerable impact on the spray dryer's performance. As a result, standardising the entering air is crucial for year-round output. The total moisture in the air as it leaves the chamber limits the capacity of the drier. The air exiting the chamber should not be excessively damp while creating a stable product, as this may result in a clumsy output. Furthermore, the chamber should maintain at the highest overall moisture level possible to achieve maximum performance. As indicated, intake and outlet temperatures and other parameters should adjust for theoretical maximum output, even during seasonal changes.

Because the laboratory spray dryer has a direct-fired gas burner that runs on natural gas or propane, it can contribute up to 10% of the moisture. It is possible to control it with a few components. You should use a hygrometer to measure the moisture content and volume of the ambient air. Finally, you should calculate the total volume of evaporated water contribution. For greater precision, mechanical inefficiency and slip should account for using a flowmeter. Finally, all operational data must be collected to appreciate the machine completely, evaluate whether it is operating at peak efficiency, and determine whether the product yield is similar to theoretical values. Food research lab offers food consulting services to assist you in using the best lab spray dryer available.

Other points to remember

-Check the air filter regularly and clean or replace it as needed.

-Inspect the seals and gaskets regularly to ensure they are intact and not leaking.

-Keep an eye on the wear and tear of the parts to prevent any unexpected failures.

-Lubricate all moving parts regularly to keep them from seizing up.

Finding replacement parts for your industrial spray dryer can be challenging, but it is important to do so if something breaks down. Here are some tips on where to look:

-Check with the manufacturer, as they may have replacement parts available.

-Look online for aftermarket suppliers who specialise in industrial spray dry